Announcement comes ahead of 2023 COP28 UAE as brand expands its accomplishments in the circular economy and sustainable action

- Brand pledges to achieve net-zero emissions by 2050 and reduce its carbon footprint by 1% annually.

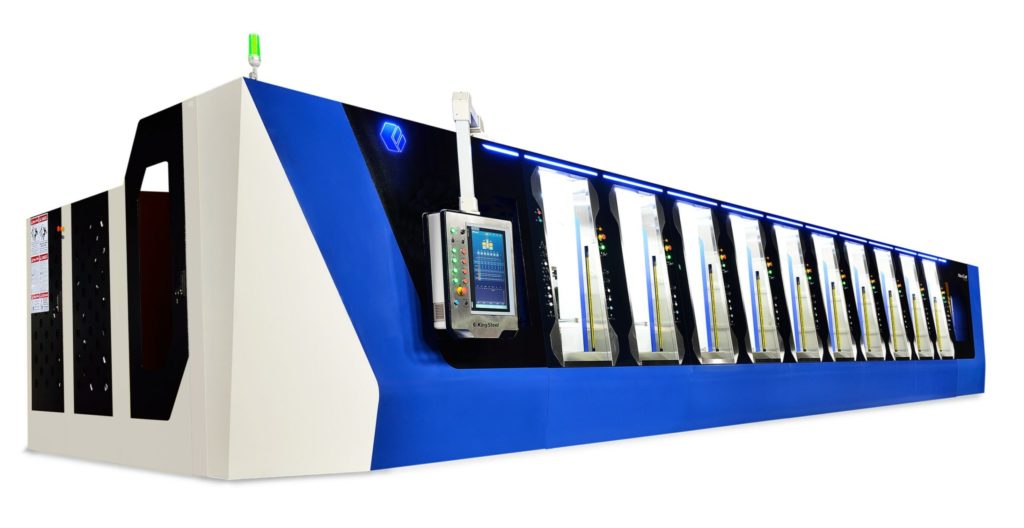

- King Steel’s NexCell machines revolutionized the shoemaking industry upon debut in 2020 by producing 100% recyclable elastomers and the capability to use recycled materials.

- King Steel’s ESG Center launched in 2022 and plays a crucial role in implementing and overseeing the brand’s sustainable practices and ESG initiatives.

Shoemaking machinery leader King Steel Machinery is publicly announcing its commitment to achieving net-zero emissions by 2050, ahead of the upcoming 2023 COP28 UAE Conference. To mark the occasion, the brand is also celebrating several recent milestones in driving sustainability throughout its operations and across the elastomer (elastic polymer) value chain central to the shoemaking industry.

For more information on King Steel’s action on sustainability, please visit: https://www.kingsteel.com/csr

Action to reduce its carbon footprint

Moving towards a greener future, King Steel first quietly made its pledge in 2022 to achieve net-zero emissions by the year 2050. Complementing this goal, the company has committed to a 1% annual reduction in its carbon footprint.

This year, King Steel also joined the RE 10×10 initiative, a collaborative effort among industry leaders to accelerate the transition to renewable energy. Furthermore, the company was honored with the Gold award in a 2023 competition organized by the Taiwanese government, which assessed and ranked the carbon footprint reduction efforts of local brands.

NexCell: The “sole” of shoemaking’s circular economy

In 2020, King Steel launched the NexCell machines, a groundbreaking innovation that is simultaneously capable of putting out 100% recyclable elastomers and using recycled materials for inputs.

Before NexCell, recycling elastomers required advanced technological methods due to their complex nature. The NexCell machines introduced the world’s first supercritical fluid-foamed elastomer injection solution, marking a pivotal change in the shoemaking industry and enabling zero-waste production processes.

The versatility of the NexCell machines extends beyond footwear, demonstrating potential applications across various elastomer-based goods. Furthermore, the foam agent used in the process contributes to carbon capturing, absorbing CO2 and aiding global efforts to combat climate change.

Embracing ESG across the value chain

These milestones are integral to King Steel’s commitment to embed Environmental, Social, and Governance (ESG) principles throughout its business operations and downstream processes. The company has fully embraced digital transformation, implementing digital-only and paperless processes to reduce its environmental footprint. To adopt these changes, in 2022 King Steel established its Sustainability Center, a hub dedicated to driving the company’s ESG initiatives. The center has significantly ramped up its activities in 2023, securing the recent ESG milestones and playing a crucial role in the implementation and oversight of sustainable practices across the organization.

About King Steel

Established in 1978, King Steel works on innovation progress of foam elastomer equipment, releasing the world’s first SCF IMM “NexCell” to inject new energy into the global circular economy and sustainable management.